R6 / R03 BODY MAKER LINES

R6R03

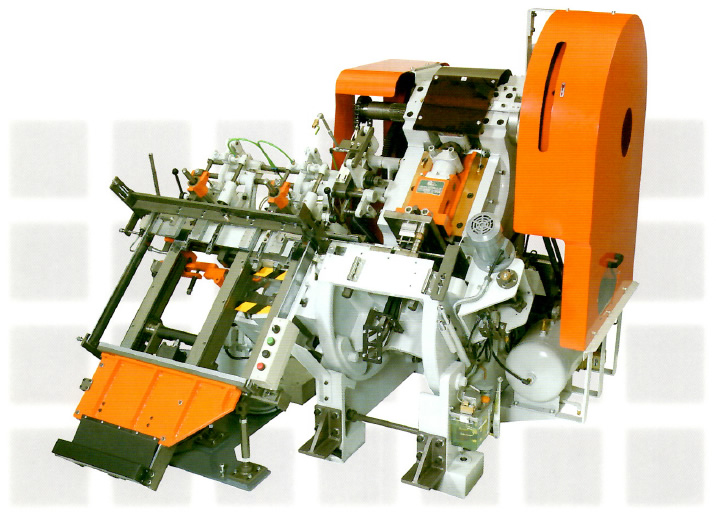

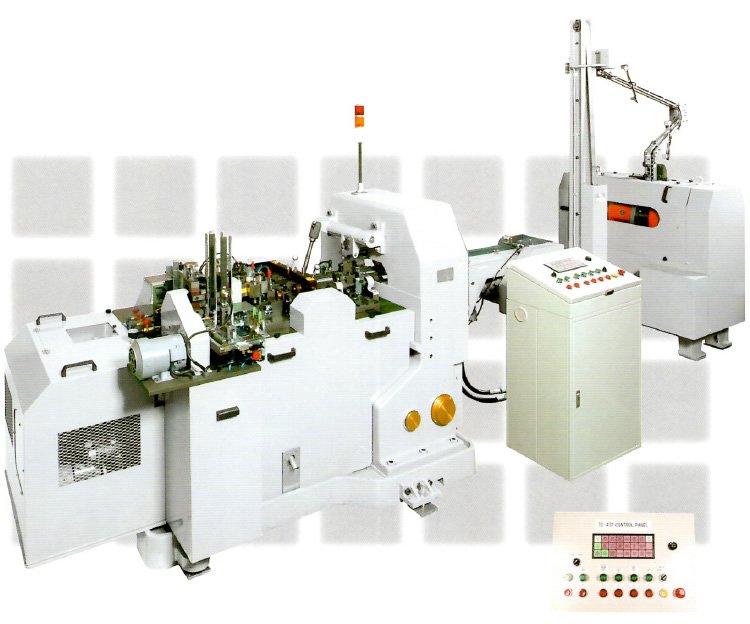

TD-435High Speed ModelR6

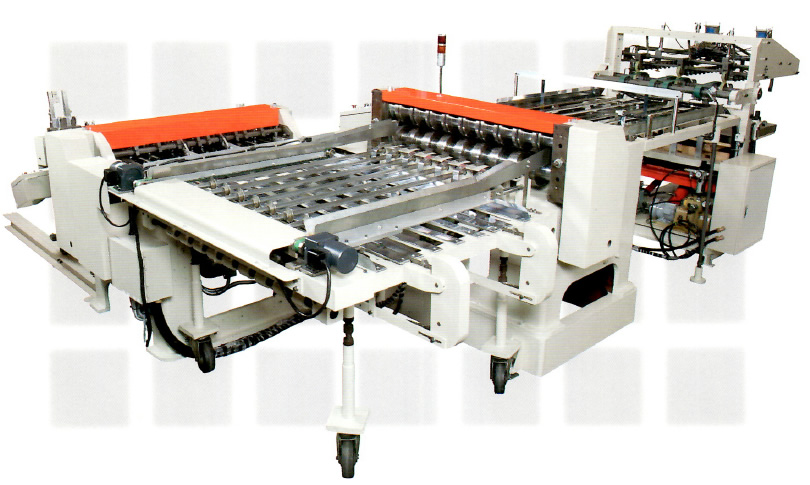

This Body maker line produces R6(UM-3) type dry battery metal jackets. Its maximum speed capacity is 800 pcs./min. The bearing system is applied to this High-speed body maker for driving parts unlike other machines,which use oil supply system. Therefore,rotation of driving parts is smooth and the level of vibration is extremely low. Besides,strokes are short and weight of machine parts is much lighter than those of other body makers. Moreover,the adjustments of timing for each stage such as suction,bumping and forming stage is very easy because dial-adjusting system is also applied to this body maker.

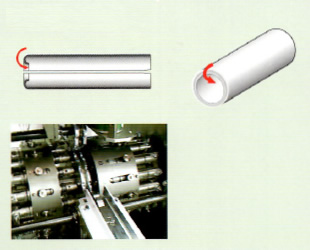

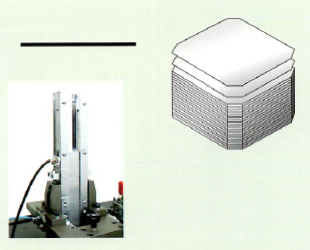

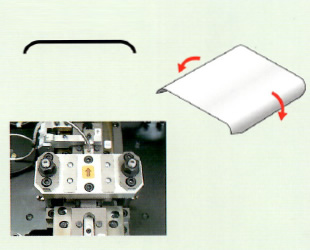

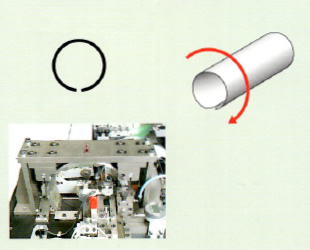

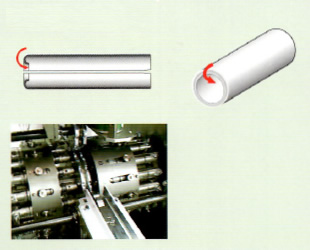

Firstly,place the blanks punched by the Automatic press machine into the Blank stacker of this Body maker(TD-435). Secondly,blanks are automatically fed to the Bumping stage one by one where the both sides of blanks are slightly bent as previous process,so that the blanks can be formed in cylindrical shapes correctly. Thirdly,blanks are fed to the Forming stage where the Cylinder forms bumped blanks perfect round shapes. Fourthly,formed metal jackets are fed to the Magnetic belt conveyer(TD-535),which delivers formed metal jackets by the Transfer turret to the Rotary flanger(TD-635) where one side of dry battery metal jackets are curled. Finally,completed metal jackets come out of this Rotary flanger.

Entire this Body maker line is operated either automatically or manually on the System line control panel. All types of mechanical troubles will be detected immediately by the sensors and will stop operation automatically.

This Body maker line is designed for easy adjustment and easy maintenance.

Specifications

| |

Body Maker & Belt Conveyer

TD-435+TD-535 |

Rotary Flanger

TD-635 |

Total

TD-435 Line |

| Production Capacity |

700-800 cans/min |

- |

700-800 cans/min |

| Horse Power Required |

5.0 kVA |

- |

5.0 kVA |

| Air Required |

350 l/min |

- |

350 l/min |

| Pressure Required |

0.6 MPa |

- |

0.6 MPa |

| Height Overall |

1420 mm |

1200 mm |

1420 mm |

| Floor Space Overall |

1680 mm x 650mm |

950 mm x 950 mm |

2630 mm x 950 mm |

| Measurement |

1.55 m3 |

1.08 m3 |

3.55 m3 |

| Net Weight |

1100 kg |

960 kg |

2060 kg |

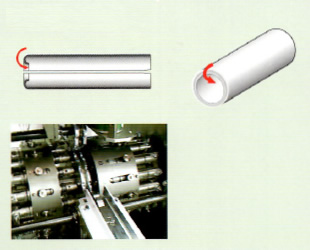

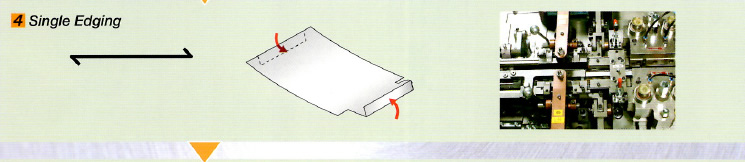

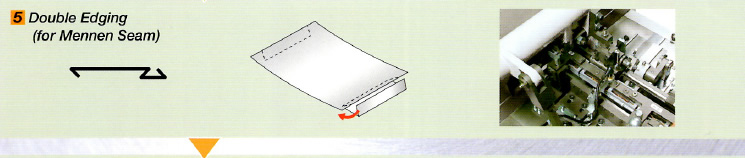

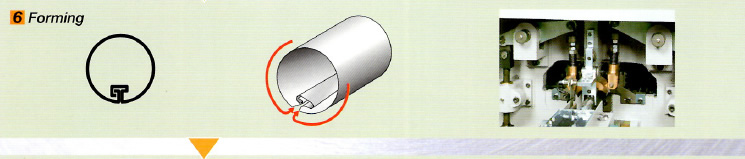

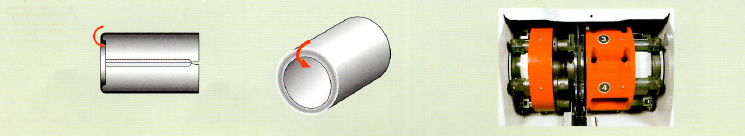

Jacket Production Process

-

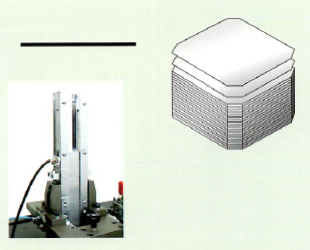

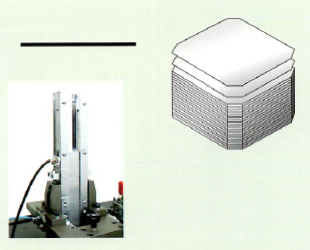

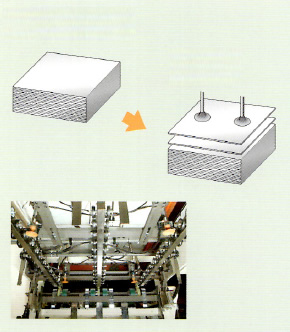

1 Blank Piling

1 Blank Piling

-

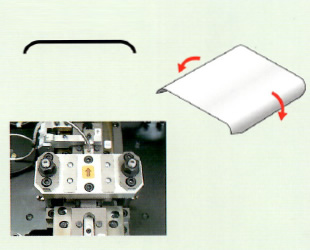

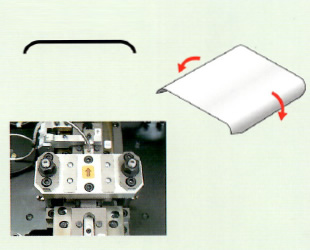

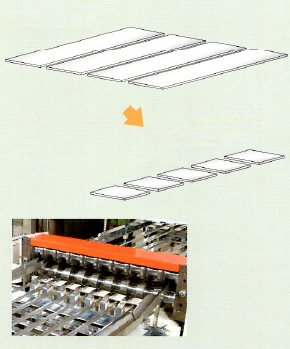

2 Bumping

2 Bumping

-

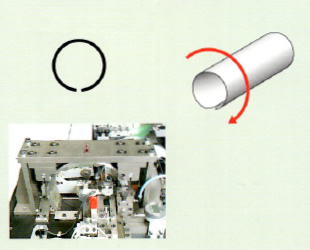

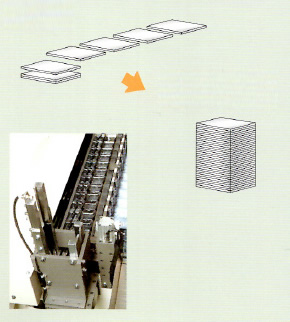

3 Forming

3 Forming

-

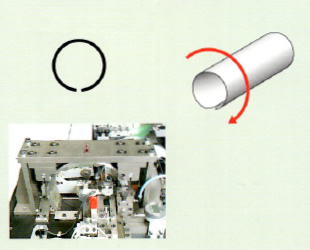

4 Curling

4 Curling

TD-434R6

TD-436R03

This Body maker line produces R6(UM-3) type dry battery metal jackets. Its maximum speed capacity is 350 pcs./min. Firstly,place the blanks punched by the Automatic press machine, into the Blank stacker of this Body maker(TD-434). Secondly,blanks are automatically fed to the Bumping stage one by one where the both sides of blanks are slightly bent as previous process,so that the blanks can be formed in cylindrical shapes correctly. Thirdly,blanks are fed to the Forming stage where the Cylinder forms bumped blanks perfect round shapes. Fourthly,formed metal jackets climb up the slope of the Elevator runway(TD-534) by the pitch belt and rolled down to Rotary flanger(TD-634) where one side of dry battery metal jackets is curled. Finally,completed metal jackets are one by one ejected from the Rotary flanger.

Entire this Body maker line is operated either automatically or manually on the System line control panel. All types of mechanical troubles will be detected immediately by the sensors and will stop operation automatically.

This Body maker line is designed for easy adjustment and easy maintenance.

Specifications

| |

Body Maker

TD-434/TD-436 |

Elevator Runway

TD-534/TD-536 |

Rotary Flanger

TD-634/TD-636 |

Total

TD-434/TD-436 Line |

| Production Capacity |

350 cans/min.for TD-434

300 cans/min.for TD-436 |

- |

- |

350 cans/min.for TD-434

300 cans/min.for TD-436 |

| Horse Power Required |

5.0 kVA |

- |

- |

5.0 kVA |

| Air Required |

300 l/min |

- |

- |

300 l/min |

| Pressure Required |

0.5 MPa |

- |

- |

0.5 MPa |

| Height Overall |

1200 mm |

1750 mm |

1460 mm |

1750 mm |

| Floor Space Overall |

1855 mm x 705mm |

1400 mm x 500 mm |

910 mm x 1300 mm |

4165mm x 1300 mm |

| Measurement |

1.57 m3 |

1.23 m3 |

1.73 m3 |

9.48 m3 |

| Net Weight |

1700 kg |

100 kg |

1080 kg |

2880 kg |

Jacket Production Process

-

1 Blank Piling

1 Blank Piling

-

2 Bumping

2 Bumping

-

3 Forming

3 Forming

-

4 Curling

4 Curling

SLITTER LINES

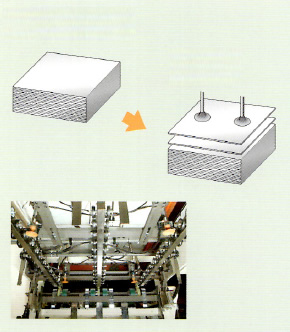

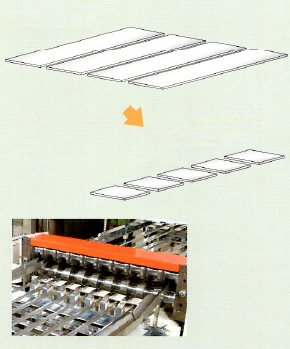

This system is used for cutting metal blanks sized for R20 and R14 dry batteries and it is assembled of Sheet feeder(TD-101),Tandem slitter(TD-211) and Blank piler(TD-311). Set the printed metal sheets in the Sheet feeder,the printed metal sheets are fed to the Tandem slitter(which is consist of the First slitter,the Turntable and the Second slitter) one by one. Going through the First slitter(cut to strips) and the Second slitter(cut to blanks),they are cut to the fixed blanks. The blanks are sent to the Blank piler and are piled up in the Stacker(capacity of piling up is 1,000-1,200 blanks). Then the blanks piled up are moved to the Body maker. When Tandem slitter and Sheet feeder are combined with this Blank piler,a series of operations(from feeding printed sheets to piling up blanks) are performed automatically.

Auto-Manual control system is set in each machine,which enables all machines to operate automatically or to operate individually. And it is convenient for adjustment of each machine.

For the slitting process for R6 and R03 size strips,the slitter line is assembled of Sheet feeder,Tandem slitter and Down stacker(TD-313). Tandem slitter is assembled of the First slitter(trim the both sides of metal sheets) and the Second slitter(cut to strips). Therefore,the Blank piler is not needed for making R6 and R03 size blank slitting process.

Jacket Production Process

-

1 Printed Sheets

2 Feeding

1 Printed Sheets

2 Feeding

-

3 1st Slitting

4 2nd Slitting

3 1st Slitting

4 2nd Slitting

-

5 Piling

6 Pile Stacking

5 Piling

6 Pile Stacking

TD-101Sheet Feeder

R20R14R6R03

This machine is used for feeding printed sheets for dry battery metal jackets. When printed sheets are set on this Sheet feeder and the machine is operated normally,they are fed one by one automatically to the Tandem slitter(TD-211). This Sheet feeder can be also used in combination with Single slitter.

Specifications

| Sheet Feeder TD-101 |

| Capacity |

6-25 sheets/min |

| MAX Loading Capacity |

1500 kg |

| MAX Loading Heigh |

400 mm |

| MAX loading Dimension |

980 mm x 980 mm |

| Horse Poower Required |

2 kVA |

| Air Required |

100 l/min |

| Pressure Required |

0.5 MPa |

| Measurment |

2.69 m3 |

| Net Weight |

1000 kg |

TD-211Tandem Slitter

R20R14R6R03

This is used for cutting printed sheets for dry battery metal jackets. This is assembled of the First slitter,the Turntable and the Second slitter. Following is the slitting process of R20 or R14 blanks. Printed sheets,which are fed to the First slitter,are cut to strips,and the strips are sent to the Second slitter,where they are cut to blanks in a fixed size(R20 or R14 size). Following is the slitting process of R6 or R03 size strips. Printed sheets,which are fed to the First slitter,are trimmed both side,and the trimmed printed sheets are sent to the Second slitter,where they are cut to strips. When this machine is combined with Sheet feeder(TD-101),printed sheets are fed automatically.

Specifications

| Tandem Slitter TD-211 |

| Capacity |

6-10 sheets/min |

| MAX Cutting Size |

980 mm x 980 mm |

| Number of Cutter |

1st: 7 sets |

| 2nd: 14 sets |

| MIN Width of Blank |

1st: 65 mm |

| 2nd: 85 mm |

| Horse Power Required |

3 kVA |

| Measurment |

13.13 m3 |

| Net Weight |

3200 kg |

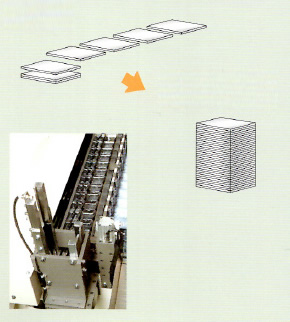

TD-311Blank Piler

R20R14

This machine is used for piling up blanks(R20 or R14) for dry battery metal jackets. Blanks which are cut by Tandem slitter(TD-211) are gathered and piled up in this Blank piler(capacity of piling up is 1,000-1,200 blanks). For the slitting process for R6 or R03 size strips,the slitter line is assembled of the Sheet feeder,the Tandem slitter and the Down stacker(TD-313). The Down atacker is the stacker of strips,which automatically move down when the number of strips on the Down stacker increases. The Blank piler is not needed for R6 or R03 size slitting process. When the Sheet feeder(TD-101) and the Tandem slitter(TD-211) are combined with the Blank piler(or the Down stacker),a series of operations are performed automatically.

Specifications

| Blank Piller TD-311 |

| Capacity |

5-8 strokes |

| Range of Accumulation

(Width) |

45 mm - 60 mm |

| Range of Accumulation

(Length) |

85 mm - 120 mm |

| Horse Power Required |

1 kVA |

| Air Required |

100 l/min |

| Pressure Required |

0.5 MPa |

| Measurement |

1.36 m3 |

| Net Weight |

850 kg |

1 Blank Piling

1 Blank Piling

2 Bumping

2 Bumping

3 Forming

3 Forming

4 Curling

4 Curling

東邦金属工業株式会社

東邦金属工業株式会社

Control Panel

RD-635 Rotary Flanger

Control Panel

RD-635 Rotary Flanger

Control Panel

Control Panel

Control Panel

Control Panel

Control Panel

Control Panel

Control Panel

Control Panel